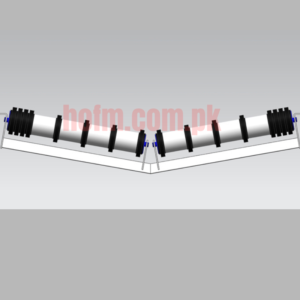

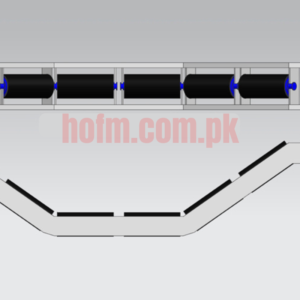

Description

Handling garland rollers requires proper safety procedures and consistent maintenance to ensure reliable conveyor performance and reduce operational risks.

By following correct handling techniques, workers can prevent equipment damage, avoid injuries, and maintain smooth material flow across the conveyor system.

Regular inspection of garland rollers helps identify early signs of wear, misalignment, or component failure, allowing for timely repairs and minimizing costly downtime.

Effective maintenance routines—such as cleaning, lubrication where applicable, and replacing worn rollers—extend the lifespan of the conveyor and improve overall efficiency.

Whether used in mining, material handling, or industrial processing, understanding the correct methods for handling and maintaining garland rollers is essential for safe,

uninterrupted operation and long-term equipment reliability.

Reviews

There are no reviews yet.